-

About

-

Products

- By Timber Product

- Cladding

- Decking

- Joinery

- Screening

- Panelling

- View all

- By Application

- Exterior Cladding / Siding

- Exterior Rain Screen

- Exterior Roofing

- Interior Walls & Ceilings

- Soffits

- Screening, Fins & Battens

- Windows, Doors & Joinery

- Posts & Beams

- Accessories

- Coatings

- Fixings

-

Resources

- By Resource Type

- Technical Data Sheets

- Guides & Manuals

- Technical Articles

- Profile Drawings

- View all

- How To

- How to Specify

- How to Install

- How to Maintain

- Projects

- Contact

Vulcan Shingles / Installation Tips and Tricks

On the release of our new Vulcan Shingles product, we reached out to a shingles installation expert for some advice

Timber shingles have been in use across the world for centuries, with the first machine fabricated shingles created in the early 19th century by steam powered sawmills. However, while they have seen something of a resurgence in modern architecture due to a pleasantly varied granular texture and rustic overtones, installation methods remain something of a lost art.

As an advanced heritage roofing specialist, Jamie MacDonald of Alba Roofing in Auckland has worked with cedar shingles and other heritage products such as slate for over twenty years. He has worked on many historical restoration projects, especially in his home country of Scotland.

Up until recently, he has only worked with cedar shingles, lacking an alternative with the strength required for roofing projects. As our unique installation system simplifies some of the steps needed when using cedar, we have included any variances for Vulcan Shingles below his recommendations.

Advice for Application

Point 1. Measure the pitch of the roof.

Jamie says: Begin by finding the pitch, to determine whether shingles can be used. To avoid water ingress, the slope can’t be any less than 15 degrees.

For Vulcan Shingles: We recommend a pitch of more than 18 degrees to ensure water tightness.

Point 2. Determine how many shingles are required.

Jamie says: Measuring the square meterage of the roof will help you ascertain how many shingles you need to purchase. Most cedar shingles come in bundles, with each bundle covering around 2.2m2.

For Vulcan Shingles: We supply shingles in two widths, 90mm and 120mm, and our product comes in mini bundles of 6 pieces each, with a single width in each bundle. For the 90mm product you will need approximately 76 pieces per square metre while for the 120mm you will need 58 per square metre.

Point 3: Securing the shingles.

Jamie says: Shingles should be secured with stainless steel or silicon bronze nails or staples. Do not use galvanized as it will rot, or copper because it can react with the timber.

For Vulcan Shingles: The same is true and Abodo recommends using stainless steel 316 fixings for best in class performance, especially when the head is exposed to weather and in sea spray zones.

Point 4: Safe storage

Jamie says: Keep the shingles in a dry, sheltered area, stored horizontally and off the ground to prevent any moisture getting in or any movement of the timber.

For Vulcan Shingles: This is also true of Abodo Shingles, with a storage recommendation of 100mm off the ground at all times. Shingles should also acclimate to the environment if brought in from other parts of the country.

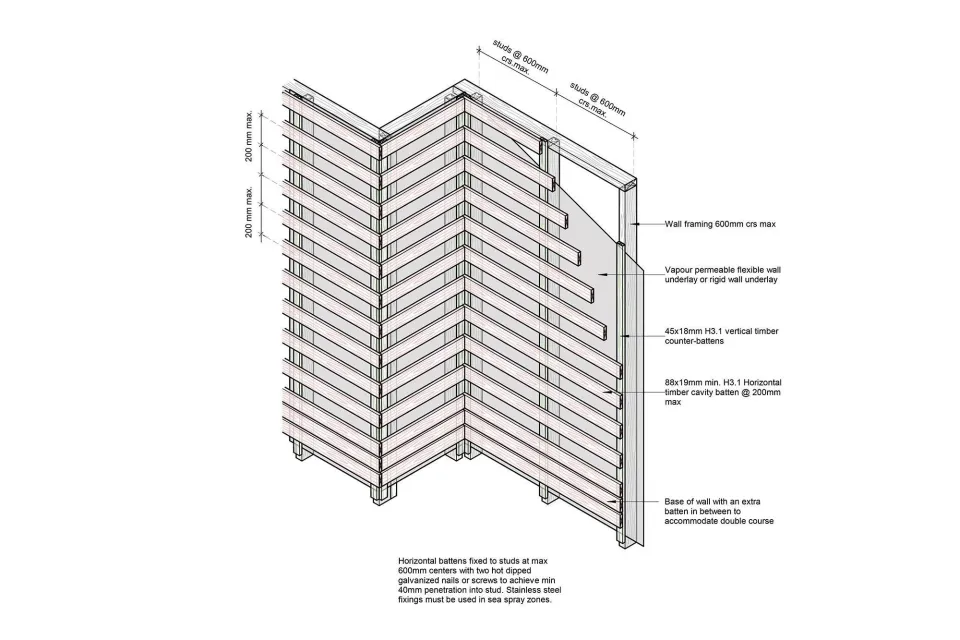

Point 5: Tools and materials required.

Jamie says: You will need an air compressor, compressing gun, a roofing knife and a circular saw. A breathable underlay is required to prevent moisture building up, as water can get trapped between and under the shingles. Drainage mats can also help with this, allowing the water to drain onto the substrate.

For Vulcan Shingles: The same tools will generally be required when installing Vulcan Shingles, however due to our unique ventilation cavity system, air can flow beneath the shingles to reduce moisture build up, making drainage mats unnecessary. For roof pitches of 18 - 30 degrees, underlay is required between each layer of shingles. For greater than 30 degrees, underlay is not necessary between layers.

Point 6: Finishing the Shingle Roof

Jamie says: It can also help to use handmade or custom made hips and ridge cappings which overlap to stop water coming in.

For Vulcan Shingles: Hip and ridge cappings can be made using standard Vulcan Shingles. Plus all installation accessories, such as screws, Vulcan cover board, fascia and cavity battens are available through our order system.

How our product differs from traditional shingles.

Of course technology has changed greatly since the steam power sawmills of the past. Interestingly though, steam is still a factor in the creation of Vulcan Shingles, which use thermally modified Forest Stewardship Council® (FSC®) certified Radiata Pine to create a product that is as durable as its cedar counterparts, without the environmental cost of transport and the loss of old growth forests.

The uniquely engineered vertical grain of Vulcan timber adds stability to each and every Vulcan Shingle.

With our unique ventilation cavity detail prompting air flow, moisture build up will be reduced while improving water tightness. The timber is also treated with a low-VOC, water-based OPX preservative treatment that guards against mould and insects, which helps create a lasting and strong product. For more detailed information on installation, please consult our Technical Data Sheets.